SERVICE PRODUCTS

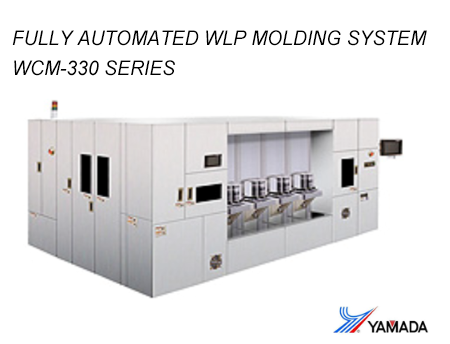

Moldig system

|

Specifications:

|

|

Specifications: |

|

Specifications: |

|

Specifications: |

|

Specifications: |

|

Specifications: |

|

Specifications: |

|

Specifications: |

|

Specifications: |